Clips, die breaks, cuds and more

A planchet is distinguished from a simple coin blank by having a raised rim. This rim is

applied to the blank by an upsetting mill, which compresses the blank's edge as it is spun between two beveled surfaces.

Planchet errors encompass all mistakes resulting from a defective blank, whether or not it has passed through the upsetting

mill. One error that can occur is for the planchet to be counted and bagged without going through the press at all. The result

is a blank planchet, which may or may not be milled. Mint-error collectors look for blank planchets when sorting through a

bag of coins, since there is little chance that a blank planchet will be wrapped in a roll or reach circulation undetected.

Wrong planchet

The most basic type of planchet error is when the wrong planchet is fed into a press. Since both the loading tube and the

die collar are sized for the appropriate denomination of coin, only planchets of the correct or smaller size can be struck

within the press. This means that a dime planchet can be struck by quarter dollar dies, but a quarter dollar planchet cannot

be struck by dime dies, since it won't fit into either the feeder tube or the collar. In January 2000, at the Florida United

Numismatists (FUN) show in Orlando, Fred Weinberg handled a Georgia quarter that had been struck on a cent planchet. The

coins sold for $3,500.

Another planchet error, one that is highly sought by collectors, occurs when a planchet intended for a foreign nation's

coinage is struck by dies for a United States coin. This type of error was more common before 1984, when the U. S. Mint cut

back its production of coins for other countries. It still may occur, however, as planchets are supplied to our mints by

commercial vendors, and these vendors also service the mints of other countries. It's not impossible for a shipment of

planchets intended for one country to accidentally include those of another.

Finally, there are more subtle errors to be considered. An error coin can have the right diameter and the proper metallic

composition but the wrong weight and thickness. This might happen, for instance, if metal strip for dimes was run through

a blanking press set up to produce statehood quarter planchets. Both coins have the same color and composition, but thinner

strip is used for dimes. It should be noted that off-metal coins are scarce, but also illegal to own. Because they do not

conform to specifications, they are considered counterfeit and the government will confiscate them.

Die breaks - Cuds

Perhaps the most popular die errors are major die breaks, commonly known as 'cuds.' These occur when a portion of the

die breaks away as the consequence of a progressive crack. Though made of tool steel, dies suffer from the repeated stress

of striking planchets, and they will wear and, in some instances, crack. As these cracks deepen and reach from one edge of

the die face to another, that portion defined by the crack may actually fall away from the die. The planchet metal then

fills this void, the resulting coins showing a featureless blob where the die broke.

Foreign objects

Dies may be damaged in other ways, such as having some foreign matter compressed into their surfaces. A set screw or

some other part of the press falling onto a die can result in severe scarring that is then transferred to each coin. Bits

of wire or fibers from a brush used to clean the die will not damage it, but they can leave impressions on a coin, since

planchets are not as hard as the die face.

Clipped

A clipped coin is made long before it becomes a coin. It starts as a clipped planchet; the blank before the dies in

the coinage press strike it. A punching-cutting machine is used to make the planchets. Long rolled sheets of metal are

automatically fed into the machine and the punching-cutting machine goes up and down, cutting circle planchets out of the

thin metal strips. If the metal sheet is not lined up properly with the punch-cutting machine, straight clips can be

formed. This is because the metal is feed into the machine to far to the right or left. The punching-cutting machine will

cut circles out of the sides of the sheets, which do not fill the area cut by the punch. This leaves one side of the

planchet straight. Thus a straight clip.

If the metal is not feed into the punching-cutting machine at a steady speed, the movement of the metal does not keep

up with the punching. When this happens, the machine is cutting circle planchets out of an area in the metal that has

already been cut. This a curved clip. If the roll of metal over feeds the punch-cutting machine, the punching machine

cuts the ends of the roll. This forms ragged clips.

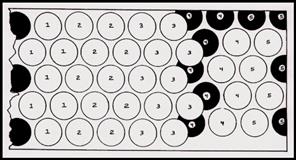

The chart below is intended as a representative example of what might occur to cause incomplete planchets.

In actuality, the planchet strip is up to 18" wide, and gang punches may have up to 80 dies to punch the blanks. The numbers

in the diagram are meant to represent 5 actions of the punch. The first, second and third are normal. The fourth punch has

slipped (likely due to a loose guide), causing the punches to overlap the edge. The 5th punch also overlapped the edge,

and overlapped the end of the strip as well. As you can see by the drawing, these various misaligned punches cause the

incomplete planchets described above.

With clipped-planchet errors, size matters-and so does the number of clips. On average, a statehood quarter with a single

clip is worth about $50 to $60. It would be worth $75 to $100 with a double clip, $100 to $150 with a triple clip. A coin

with particularly dramatic clips, or with more than three clips, could be worth even more. Conversely, a coin with relatively

small clips could be worth substantially less.