How blanks and planchets are made

Coin blanks used for striking coins can be purchased from coin blank suppliers, or be produced

by the mint itself. In making such blanks, bars are first scrubbed to provide a consistent surface, free from

impurities or imperfections which not only produce defective coins, but also reduce the life span of the dies. The

bars are later annealed and rolled to become strips of metal having the exact thickness specified of each

denomination of coin. Blanks and planchets represent the same product at

different stages of production: the unstruck, circular pieces of metal that become coins when struck between the

dies. Blanks are unfinished planchets that haven't been through all of the processing steps necessary before they

can be struck into coins. Once a blank has been through all of the processing steps, it becomes a planchet and is

ready to be struck.

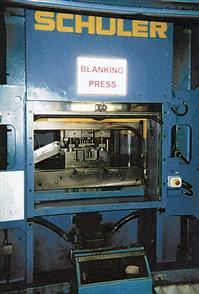

Making a blank

The first step in the coin making process involves the feeding of the metal strips through what

is known as a "blanking" press. The U.S. Mint buys strips of metal approximately 13 inches wide

and 1,500 feet long to manufacture the nickel, dime, quarter, half-dollar, and dollar. The strips come rolled in a

coil. Each coil is fed through a blanking press, which punches out round discs called blanks. The blank presses

have a bank of punches (or rams) which travel downward through the strip of coinage metal and into a steel bedplate

which has holes corresponding to the punches. The presses punch out blanks each time the punches make their

downward cycle. The leftover strip, called webbing is shredded and recycled. The blanks made at this stage are

slightly larger than the finished coins. Because of the shearing action of the punches, the blanks have rough edges.

Most of the rough edges (or burrs) are removed during succeeding operations.

The blanks are next passed over sorting screens which are supposed to eliminate all of the

defective pieces. Thin and incomplete blanks will fall through the screens. Rejected blanks and remaining parts of

the metal strips are returned to the furnaces to be remelted into bars. During the finish rolling and blanking

press operations the blanks have again been hardened and must now be softened (heated) to controlled temperatures,

approximately 1400 degrees Fahrenheit, changing their crystal structure to a softer state. The annealing

ensures that the blanks have reached a coinable hardness so that they can be stuck to capture the full relief of

the designs of the working dies. This process prolongs the life of the coining dies by ensuring well-struck coins

with lower striking pressures. The blanks are then "frozen" into that state by a water quench bath.

From planchets to coins

Despite a protective atmosphere, annealing causes some discoloration on the surfaces of the

blanks which must be removed. The blanks are tumbled against each other and passed through a chemical bath. Then

they are dried by forced hot air. Many of the blanks' next stop is an upsetting mill, which raises

a rim around their edges turning the blanks into planchets. The upsetting mill consists of a rotating wheel with

a groove on its edge. The grooved edge of the wheel fits into a curved section (or shoe) which has a corresponding

groove. The distance between the wheel and the shoe gets progressively narrower so that, as the blank is rolled

along the groove, a raised rim is formed on both sides of the blank. This raised rim serves several purposes. It

sizes and shapes the blank for better feed at the press and it work-hardens the edge to prevent escape of metal

between the obverse die and the collar.

The rimmed blanks are now planchets and are ready to go to the coining or stamping press where

upper and lower dies stamp the designs and inscriptions on both sides of the coin simultaneously. At this point,

the blanks become genuine coins. After the coins have been struck, they go through a final inspection to check for

flaws. This can be done either manually by trained quality controllers or automatically. A new prototype inspection

system underwent testing at the Denver Mint in 1996. Planchets are carried along a conveyor belt beneath

electronic sensors that reject substandard pieces. After inspection and acceptance, the finished coins are

mechanically counted and placed into large canvas bags for shipment to local banks on an as-needed basis. More

about the actual striking process in the next page...